about zhongfu

Our company mainly specializes in open die forging, heat treatment and machining.

Jiyuan Zhong fu Machinery Manufacturing Co., Ltd. was founded in 2003,located in Jiyuan City, Henan Province. Our company mainly specializes in open die forging, heat treatment and machining. We have a batch of heavy machinery equipment, experienced staffs and a strict quality assurance system. And we have very intensive cooperations with domestic leading heavy Industry groups, such as Taiyuan Heavy Industry, Northern Heavy Industries Group Co., Ltd., and our products have been exported to Japan, Russia, India, Turkey , Europe and other countries and regions.

Was founded in 2003

Our forging workshop has a 2000-ton hydraulic press

A 20-Ton full hydraulic manipulator

Passed ISO9001 certification in 2007

our products

Our company mainly specializes in open die forging, heat treatment and machining.

If you have any cooperation intentions or suggestions, please contact us!

National consultation hotline

Our advantage

Our company mainly specializes in open die forging, heat treatment and machining.

Rich production experience

Jiyuan Zhongfu Machinery Manufacturing Co., Ltd. was established in 2003 and is mainly engaged in free

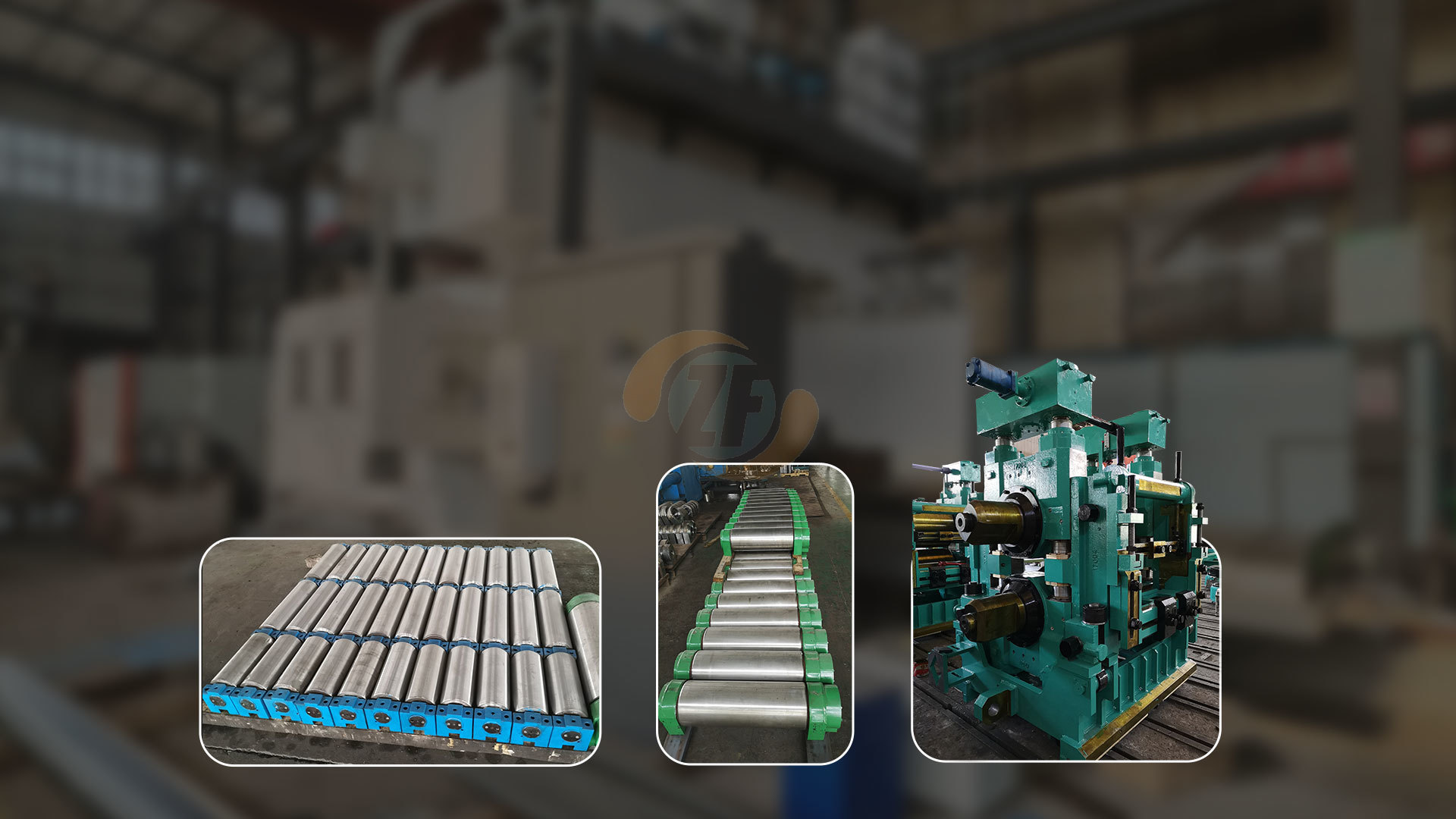

Complete production equipment

Presses, annealing furnaces, pit quenching and tempering furnaces, box furnaces, metal cutting machine tools

Strict quality control system

Passed ISO9001 certification in 2007. In addition, we have long-term cooperation with SGS and BV companies to

Close partner

We have very close cooperation with leading domestic heavy industry groups such as Taiyuan Heavy Industry

Our company mainly specializes in open die forging, heat treatment and machining.

If you have any needs, please call the national unified service hotline

News Center

Our company mainly specializes in open die forging, heat treatment and machining.

Representative technologies in the development process of continuous casting technology(Ⅰ)

The 1950s marked a decade of breakthrough progress in continuous steel casting. In 1950, the world's first vertical continuous casting machine for industrial production was put into operation at the Huligen plant of Mannesmann Company in Federal Germany. Subsequently, 15 (40 stream) industrial casting machines from different countries were put into operation one after another. China began continuous casting experiments in 1954, and in 1957, the central laboratory of Shanghai Iron and Steel Company first built an industrial scale vertical testing unit. In 1958, Professor Xu Baolong from Beijing Institute of Iron and Steel designed the first rectangular billet continuous casting machine for industrial production in China, which was built at Chongqing Iron and Steel Third Plant.

14

2023-11

Representative technologies in the development process of continuous casting technology(Ⅱ)

In 1967, in order to further reduce the height of the casting machine, two ultra-low head slab continuous casting machines were built in Germany. One slab continuous casting machine at the Uss/Gary factory centralized the sliding nozzle of the tundish, automatic pouring and mold level control, and bending and straightening with liquid core.

14

2023-11

Representative technologies in the development process of continuous casting technology(Ⅲ)

By 2000, the global continuous casting ratio had reached 86%, with over 90% of countries reaching over 40. In the new century, the development of materials science has promoted the progress of the steel industry, and the improvement of steel strength, toughness, fatigue resistance, corrosion resistance and other performance has put forward higher requirements for clean steel production and defect free casting billets. The improvement and popularization of sensing and detection technologies, as well as the rapid development of computers, networks, and intelligent technologies, have endowed continuous casting technology with greater vitality.

14

2023-11

The Development History of Continuous Casting Technology

The development of continuous casting technology has a history of over 100 years. The emergence of continuous casting technology is a major revolution in modern metallurgical technology, replacing mold casting with continuous casting, making large-scale steel production possible.

14

2023-11

Continuous casting operation position

Captain. The captain is the person in charge of the steel pouring operation, responsible for the production, organizational management, equipment maintenance and use, as well as safety and civilized production of the unit; Ensure the completion of production tasks and various technical and economic indicators assigned by the workshop; Strictly follow the operating procedures during production to guide production;

14

2023-11

Continuous casting production technology, you don't understand, I'll tell you

The production of continuous casting billets refers to the production of qualified billets within a specified period of time (usually measured in months, seasons, and years). The calculation formula is:

14

2023-11

National consultation hotline

Address: No. 196, Tiantan Middle Road, Jiyuan City Province

E-mail: jyzf22828@163.com

Social media

Official WeChat

SAF Coolest v1.3.1.1 设置面板 BYGSX-ZBTX-AVZAE-AEF

无数据提示

Sorry,There is currently no content in the current column!

You can view other columns or return to Home